ПОЛОТНА ДЛЯ ЛЕГКИХ МАТЕРИАЛОВ ИЗ СПАН БОНД

Спанлейд-материалы / Иглопробивание / Химическое скрепление

Кровельный материал плотностью 120-250 г/м2

Геотекстиль 150-500 г/м2

Complete production lines for Spunbonding roofing carriers and geotextiles

The line is Used for the production for roofing, Civil engineering, Technical felts, Separators for batteries, Carriers of PVC flooring.

After the forming, the web is needle punched, thermo fixed, calibrated, impregnated, pre dried, dried, cured, calibrated and rolled.

Technology

Full compatibility for processing either PP or PET polymer; Possibility of use of PET flakesasan alternativeto PET chips;

Filament scooling and stretching, with indipendent positions and individual round ejectors, fed by low pressure air that guarantees operational continuity and stability of the filaments characteristics over time;

BalancedtensilestrengthratioMD/CD.

The product

Binder impregnated fabrics for roofing (120-250gsm)

Needle-punched fabrics for geotextile(150-500gsm)

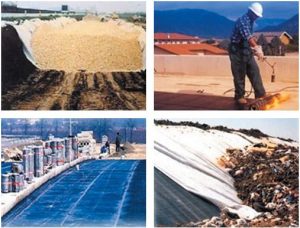

The application fields

civilengineering, hydraulic works,

landfills

- Carpet backings

- Coating substrates

Binderimpregnatedfabrics

- Roofing Carriers

- Filter media

The raw materials

•Humidity content: less than 0.8%

•Intrinsic viscosity: 0.60to0.75 dl/g

•PVC/contaminants: less than 200ppm

•Size: 3-12mm

•Humidity content: less than 0.4%

•Intrinsic viscosity: 0.60 to 0.75dl/g

•PVC/contaminants: less than 200ppm

• Molecular weight distribution MW: Narrow

•Isostaticity: ≥96%

•Humidity content: ≤0,05%

•Ash content: ≤250ppm

Tecnical Features

WORKING WIDTH: up to 6m

PRODUCTION CAPACITY: up to 10,000 tons/year

SPACE REQUIREMENTS(*)

Production room: 2,100 sqmin cluding:

Spinning area (height 14m): 600 sqm

Finishing area (height8.5m): 1,500sqm

Raw materials warehouse: 1,000sqm

Finished prod. warehouse: 1,000sqm

UTILITIES-[units perton of product](*)

Electric power: approx 1,700kWh

Fuel equivalent to 1,700,000kcal

Industrial water: approx 1m3

Compressed air: approx 500Nm3

(*)Refered to a plant 4 m width, not binding information