Ovens

Flat stenter

The Sicam stenter frame can tell a story more than fifty years long:

since when they were used in the sixties in the textile uses or in the eighties at the introduction of the nonwovens, till the most modern process innovation of these years.

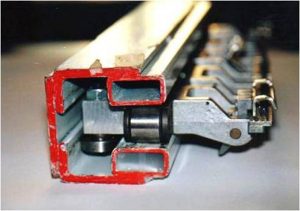

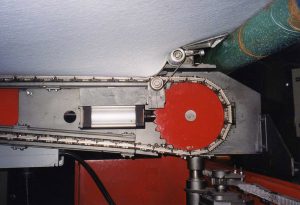

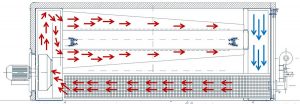

Sicam has developed an efficient impingement ventilation that works both on the top and on the bottom surface of the material. The transport of the material is by pin chains working on bearings. This system allows the tensioning of the material during the heating and allows high production speed.

In the nonwovens the Sicam stenters are used in the high speed needle punching lines to correct the orientation of the fibers and to thermoset the felt.

The Sicam stenters are used in addition for drying and thermosetting in the lines for coating and impregnation and for the thermobonding process for the cleaning pads.

The sicam stenter is composed mainly by:

Introduction conical section

The multisection aerothermic chamber

The impingement ventilation system on the two sides

In addition we find the construction Sicam philosophy without sliding elements. this solution make possible an easy access and to inspect inside the oven reducing the maintenance time and costs.

The construction philosophy by modular section of 2250 mm of length, used by Sicam since many years in its production range, makes easy the transport operation all over the world allowing a simple load in containers if preassembled machinery sec.

Technical features

| Working with: |

2000-3500 mm |

| Production speed: |

2- 100 m/min |

| Product weight: |

100-500 gsm |

| Maximum working temperature: |

200 °C |

| Heating systems: |

gas burners diathermy oil, steam, electric heat exchangers |