Ovens

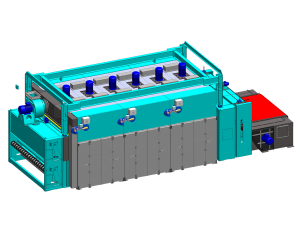

MULTIpro oven

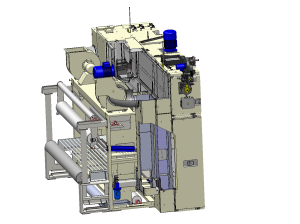

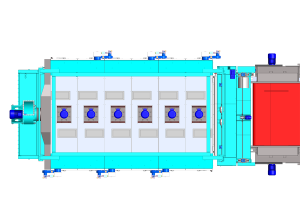

The combination of the experience, that characterizes SICAM, with constant research and development of new solutions has enabled the company to design and be able to offer its customers a modern type of oven, with innovative and patented solutions.

This oven, as well as being improved in the main design and quality features, has the distinction of concentrating in a single machine all the technical solutions that enable the optimal production, within the same line, of nonwovens at odds with each other, as felts and wadding. A wide range of nonwovens, which are usually produced with specific ovens, in this case can be contemplated within the same oven and this is the real novelty introduced by SICAM.

The various experiences of SICAM in recycled felts ovens and in wadding ovens are then conveyed in a single oven; This SICAM patent combines the solutions of extreme simplicity of cleaning and access, which are linked to recycled felts ovens, to the most sophisticated technologies on ventilation, which are related to the thermobonded polyester wadding.

In addition, the oven MULTIpro SICAM is characterized by an efficient energy recovery system, which, besides to recovering the energy, increases the productivity of the oven. In fact, on the basis of another SICAM patent, there is an increase in productivity and profitability of the oven thanks to the heat recovery of the exhausted fumes, conveyed in the entry head that is used as an additional hot section to the oven for preheating.

MULTIFUNCTIONALITY

The novelty of the SICAM oven, which involves interesting aspects from the commercial point of view for the customer, is the multifunctionality, allowed by the particular design philosophy and SICAM patent.

Usually an oven is specifically designed on the basis of the different types of material and process, accepting the limitations on the scale of product range, limit which is, however, in collision with a rapidly changing market. SICAM has managed to propose a machine that offers a highly flexible product range, which is useful to the customer to try out new business taking the opportunity of the moment without major investments, such as creating a dedicated line from the new.

The SICAM MULTIpro oven has 3 main aspects that allow the customer to change its product range. In fact it is possible to switch from the production of a nonwoven to that of another with extremely different characteristics, by means of adjustment operations, with the mounting of specific kits or thanks to design particularity of machinery.

Then, the SICAM MULTIpro oven guarantees production change from a nonwoven to another extremely different, thanks to:

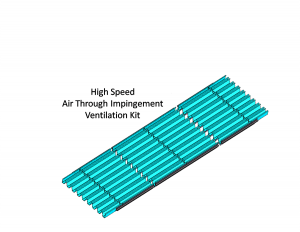

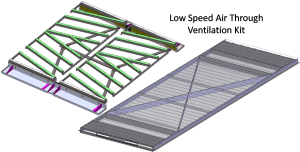

- Possibility of choice and adjustment of the ventilation type: diffused, for crossing at a low speed or by nozzles at high speed

- Adaptability both of Metal conveyor belts for recycled materials and of glass/teflon and PPS conveyor belts for thermobond polyester.

- The extreme accessibility for cleaning, which allows to treat recycled materials, fundamental requirement for reliability in the production of this type of nonwoven.

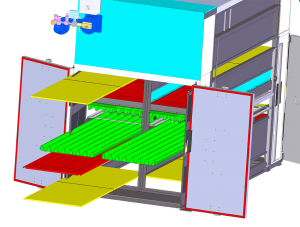

With reference to point 1, SICAM associates to MULTIpro oven a conversion kit from crossing ventilation at low speed to ventilation by nozzles at high speed.

In the condition at low speed the system for adjusting suction width is kept, while with the mounting of the kit this adjustment is no longer required for the process on the nonwoven and is therefore excluded.

The installation or removal of the kit is extremely easy thanks to a slipping mounting system.

With reference to point 2, the entrance and exit heads are designed to be able to mount both metal conveyor belt and PTFE conveyor belt, which may be driven by automatic centering devices or by gear shafts.

With reference to point 3, the ease of cleaning, useful but not determinant in the production of polyester thermobonded, makes possible the use of this oven for the production of recycled felts bonded with polypropylene.

In conclusion, the same oven can ensure the production of nonwovens extremely different from each other simply with the conveyor belt replacement kit and with the blowing elements replacement kit.

ENERGY RECOVERY SYSTEM

The second interesting feature is the new SICAM patented energy recovery system, which brings higher efficiency benefits to the customer than other solutions on the market.

For the purpose of an optimal ventilation balance, a part of the circulation air must be evacuated and unfortunately this air dissipates a substantial amount of energy that could be partially recovered.

The novelty of the SICAM energy recovery system is to act through the combination of the two following technical solutions:

- The heat recovery system, that, forcing the exhaust air through the material, preheats it.

- The installation of such heat recovery system in the entrance head of the oven, thus recovering a heated space than in conventional ovens, however, remains unused.

In this way, the hot operative length of the machinery is extended also to the entrance head zone (1125mm, which is equivalent to half of oven section). The benefits compared to an oven with a traditional energy recovery system translate into an increase in productivity (therefore in speed) for an equal number of sections (length) or in a reduction in the number of sections (so dimensions, consumptions and costs) at equal productivity.

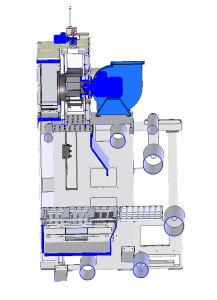

The exhausted air is sucked by the central fan of the oven by two side ducts, then the air is distributed on the material which is located in the entrance head and this air will pass through the material, thanks to the suction of a hood, underlying material and connected to the two side exhausters fans.

In conclusion, the heat recovery section positioned in the entry head (SICAM patent) preheats the material and this positioning allows not to “waste” the first section of the oven in preheating mode, as occurs in traditional ovens with heat recovery system, but to use it at full thermal power. This advantage can be interpreted, alternatively, as an increase of productivity benefits or as a reduction of overall dimensions and costs associated with equal productivity.

OTHER TECHNICAL AND PROCESS FEATURES

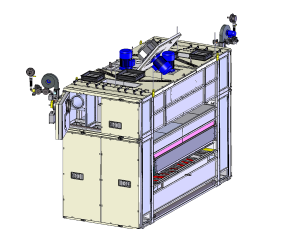

This machine is characterized by features that SICAM ovens have, such as accessibility, size of the sections of the oven suitable for container transport, ventilation evenly distributed, extreme simplicity in maintenance, reliability in function of suction width adjustment, construction of the ventilation circuit with slipping elements without necessity of using any tools.

Other targets related to the innovative design construction of this machinery are:

- ventilation suited to ovens of large working width for not having to stagger the placement of the oven sections

- reduction in transverse dimensions

- Improving accessibility

- minimization of maintenance operations

- temperatures differentiated meter by meter

- airflows differentiated meter by meter

- direction adjustable air meter by meter, maximally limiting the dimensions of the diverter valves

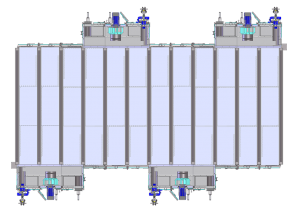

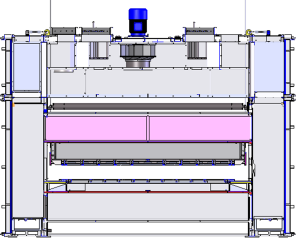

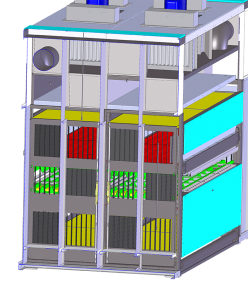

- In this SICAM project, fans are placed at the center of the top of the oven. This layout allows a symmetrical supply on the two sides of the oven to the air distributors positioned above and below the material. Thanks to this ventilation circuit, guarantees the perfect distribution uniformity of the air on the product even for extremely high working widths.

- SICAM has chosen to place all the ventilations and heating units on the top of the oven and this has allowed a considerable reduction in the transverse dimensions with equal working width.

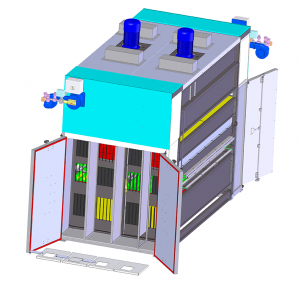

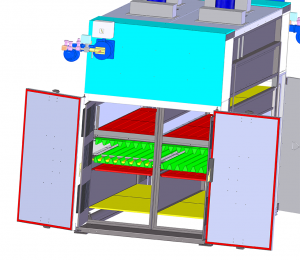

4/3 One of the best results obtained in the new project has been achieved in the accessibility and ease of maintenance.

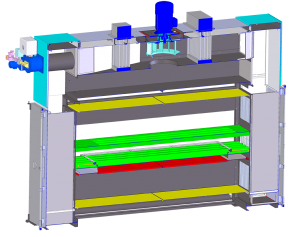

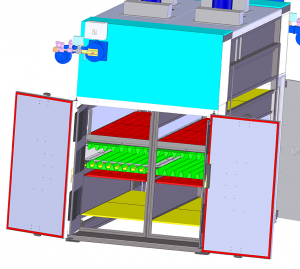

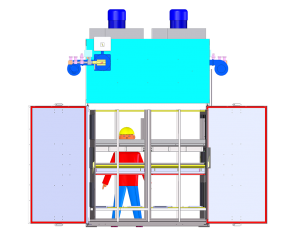

The images below shows the advantages of SICAM MULTIpro Oven in the field of accessibility and maintenance. The adoption of internal doors fitted with dampers to change the direction of the air (SICAM patent) has revolutionized the accessibility to this type of ovens.

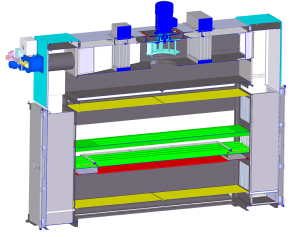

The two diagrams below shows the substantial difference between this oven and conventional ovens.

The new layout of ventilation and heating units, allows to have inspected the two sides of the oven and an to have an access that is unmatched compared to traditional ovens. Even the fans on the roof can be folded, as also ducts burners are accessible, thanks to they are mounted on the doors. Even the panels delimiting the ducts of the exhausters are removable and, with their easy removal, make inspectable all tubing.

Also the eventual operation of extraction of the return rollers is simplified, since they are all visible and accessible from the two sides with the only opening of the doors.

5/6/7 From the layout of the fans, of the burners and of the air ducts is clear that is possible get temperature, air flow and air directions differentiated meter by meter on the length of the oven. In this way the oven versatility is improved by doubling, compared to traditional ovens, the points that determine the profiles of ventilation, temperature and direction of air.

Technical features

| Working with: |

1200-5000 mm |

| Production speed: |

10- 50 m/min |

| Product weight: |

100-6000 gsm |

| Thickness at the entrance: |

up to 1500 mm |

| Thickness at the exit: |

5-200 mm |

| Maximum density at the exit: |

up to 300 kg/m3 with calender |

| Maximum working temperature: |

220 °C |

| Heating systems: |

gas burners diathermy oil, steam, electric heat exchangers |

| Adjustment of ventilation width: |

-750 mm |